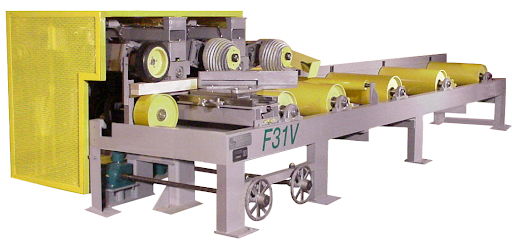

Capacity:

Thickness: 1/2″ – 8″

Width: up to 15″

Length: 8′ – 16′ behind lumber line

Feed Speed: up to 1500 FPM

Bed Height: 35″

Construction:

Steel fabricated frame C8 x 22.8 channel iron used throughout

Standard Equipments:

12″ diameter feed rolls

– reversible 12″ diameter, cast ductile, chrome pineapples

Upper rolls mechanically positioned and air loaded

Thin stock device

“Quick Lift” feature for upper rolls

Guide bar with ball bearing roller to reduce friction

Anti-lap device

Optional Equipment:

Heavy duty steel pinch roll, in lieu of rubber

Breakdown conveyor drive shaft

Knurled lower outfeed roll

Bump plate

30 HP, 1200 RPM, drive motor

AC variable speed frequency drive

4′ length modifications behind lumber line

Live bridge in lengths to suit

Capacity:

Thickness: 1/2″ – 8″

Width: 2″ – 15″

Length: 8′ – 16′ behind lumber line

Weight: 7500 lbs.

Feed Speed: Designed to suit planer speed

Bed Height: 35″

Construction:

Steel fabricated frame

C8 X 22.8 channel iron used throughout

Standard Equipments:

(2) 20 HP VFD powering one, 20 HP motor/gearbox

unit for the lower rolls and one for the pineapples and pinch roll

Heavy duty steel pinch roll

12″ diameter feed rolls – reversible

12″ diameter, chrome pineapples

Upper rolls mechanically positioned and air loaded

Thin stock device

“Quick Lift” feature for upper rolls

Guide bar with ball bearing roller to reduce friction

Anti-lap device

Optional Equipment:

Breakdown conveyor drive shaft

Spiral cut lower roll

Knurled lower outfeed roll

Bump plate

4″ length modifications behind lumber line

Live bridge in lengths to suit

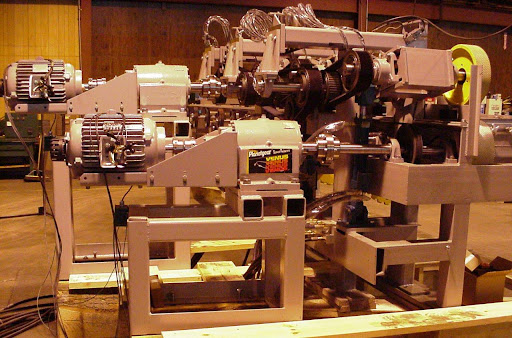

Capacity:

Thickness: 1/2″ – 8″

Width: 2″ – 15″ (20″ and 25″ optional)

Length: 8′ – 24′ behind lumber line

Weight: 7500 lbs. (15″ x16′ behind lumber line table)

Feed Speed: Designed to suit planer speed

Construction:

Steel fabricated frame

C8 X 22.8 channel iron used throughout

Standard Equipments:

(2) 20 HP Vector drives powering one, 20 HP motor/gearbox

unit for the lower rolls and one for the pineapples and pinch roll

25 gallon hydraulic unit with auxiliary valve manifold for

operation of roll adjustment cylinders and other power assisted functions

14 diameter feed rolls – reversible

14 diameter, 16 start, chrome pineapples

Upper rolls hydraulically positioned and tensioned

Thin stock device

Guide bar with ball bearing roller to reduce friction

Anti-lap device

V-belt shields – prevents slivers from knocking off belts

Complete Nema 12 enclosure for motor starters and

free standing console for pushbuttons

Adjustable pineapple roll

Optional Equipment:

Heavy duty steel pinch roll, in lieu of rubber

Breakdown conveyor drive shaft

Automatic adjustable pineapple roll

Spiral cut lower roll

Knurled lower outfeed roll

Hydraulic release stock gate

Powered even-ending stock gate

Bump plate

In-line metal detector

Capacity:

Thickness: 1/2″ – 8″

Width: 2″ – 15″ (20″ and 25″ optional)

Length: 8′ – 24′ behind lumber line

Weight: 7500 lbs. (15″ x16′ behind lumber line table)

Feed Speed: Designed to suit planer speed

Construction:

Steel fabricated frame

C8 X 22.8 channel iron used throughout

Standard Equipments:

(2) 20 HP Vector drives powering one, 20 HP motor/gearbox

unit for the lower rolls and one for the pineapples and pinch roll

25 gallon hydraulic unit with auxiliary valve manifold for

operation of roll adjustment cylinders and other power assisted functions

16″ diameter feed rolls – reversible

16″ diameter, 16 start, chrome pineapples

Upper rolls hydraulically positioned and tensioned

Thin stock device

Guide bar with ball bearing roller to reduce friction

Anti-lap device

V-belt shields – prevents slivers from knocking off belts

Complete Nema 12 enclosure for motor starters and

free standing console for pushbuttons

Automatic adjustable pineapple roll

Spiral cut lower roll (3)

• Hydraulic release stock gate

Optional Equipment:

Heavy duty steel pinch roll, in lieu of rubber

Breakdown conveyor drive shaft

Knurled lower outfeed roll

Powered even-ending stock gate

Bump plate

In-line metal detector