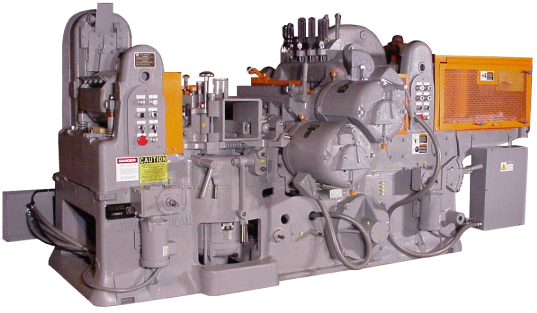

Capacity:

Thickness: 1/4″ x 8″

Width: 2 1/4″ x 15″

Length: (minimum self feed) 72″

Weight: 16,100 lbs

Controls:

Switches located in both infeed and outfeed roll stands

Right sidehead control station

Horsepower:

Top: (2) 50 (Standard)

Bottom: 50 (Standard)

Left Side: 50 (Standard)

Right Side: 35 (Standard)

Other Standard Equipments:

Split sectional type infeed rolls

Kwik release/reset of pressure bar

Kwik release/reset of left sidehead

Combined bed plate and lower infeed roll adjustment

Motor starting enclosure

Electrically interlocked safety guards

Feed system:

Mechanical

200-700 fpm

Helical gear driven rolls interconnected by chain and sprocket with an automatic lubricator

12″ feed rolls

40 HP, 1200 RPM drive motor with reversing starter and sheaves for (1) fixed feed speed

Cutterheads:

Up to 14 knives per head

Top and bottom head – one piece alloy

8 1/8″ cutting circle

3600 RPM

Mechanically interlocked brakes

Sideheads arranged for a maximum 8″ cutting circle with maximum 9 5/8″ swing

Optional Equipment:

Carbide spiral cutterheads

Sidehead cutterheads

Chrome, nickel, or carbide wear parts

Power hoists for infeed and outfeed rolls

Power hoist for top head

Hydraulic roll tensioning

Air release chipbreaker

Double profiles

Feed reduction unit for 75-400 fpm

Free standing operator’s console

Roller knife setting gauge

AC variable speed frequency drive

Construction:

Cast blade with heavy internal cross members

All major components are cast

Capacity:

Thickness: 1/2″ x 6″

Width: 2 ¼” – 15″

Length: (minimum self feed) 90″ (59″ w/mid roll)

Weight: 25,000 lbs. (6 roll machine)

Controls:

Free standing operator’s console

Pendant control station

Guide sidehead control station

Horsepower:

Top: 100

Bottom: 75

Out Side: 50

Guide Side: 40

Other Standard Equipments:

Chipbreakers – air tensioned/released

LCD digital readout – top head, bed plate, bottom head, and lower feed rolls

Pneumatic sidehead hold-over roll and infeed hold-over guide

Built-in top and bottom jointers with “safe stone advance”

Detachable sidehead jointers

Hydraulic top and bottom head lock

Top and bottom dust hoods

Electrically interlocked safety guards with easy access

Quick-release pressure bar and outside head

Electrical panel

Automated bottom head traverse

Automated top head hoist

CE certified

Feed system:

Mechanical

Electric or hydraulic drive

Maximum feed speed – up to 1000 FPM

14″ feed rolls

Upper rolls hydraulically positioned and tensioned

All feed rolls reversible, interchangeable

Cutterheads:

All cutterheads – 10 ¼” diameter cutting circles

Up to 16 knives/head (20 knives optional)

“Dura-Change” heads

Optional Equipment:

8″ thickness capacity

24″ width capacity

Spiral carbide cutterheads

Hydraulic pressure bar control

Sidehead cutterheads and tooling

Automated setworks – top head and outside head

Double profile

Water cooled main guide

Programmable controller

Alternative voltage to 460 standard

Powered mid roll assembly

Frequency inverters to increase spindle speeds

Complete lumber infeed/outfeed equipment

Larger horsepower cutterhead motors

Left hand guide registration

Construction:

Steel fabricated frame

Thermally stress relieved

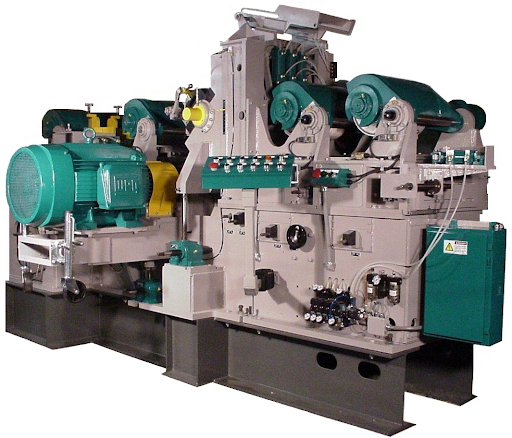

Capacity:

Thickness: 1/2″ X 6″

Width: 2 1/2 X 13

Length: (minimum self feed) 95″

Weight: 34,000 lbs.

Controls:

Pendant control station

Right sidehead control station

Horsepower:

Top: 150 (Standard) 200 (Optional)

Bottom: 100 (Standard) 125/150 (Optional)

Outside: 75 (Standard) 100 (Optional)

Guide Side: 75 (Standard) 100 (Optional)

Other Standard Equipments:

Steel sub-frame

Siko counters for bed plate, and lower feed roll adjustment

Motorized top head hoist

16 knife top and bottom cutterheads

Reversible feed rolls

Chipbreaker – air tensioned/released

Pneumatic sidehead chipbreaker and infeed hold-over shoe

Built-in “safe stone advance” jointers

Hydraulic top head lock

Hydraulic bottom head lock

Top and bottom dust hoods

Electrically interlocked safety guards

Quick-release left sidehead

Digital positioners – top head and left sidehead

Oil injection lubrication system for cutterhead bearings

Programmable controller

Feed system:

Mechanical

2000 fpm (various speed ranges to 2000 fpm)

Hydraulic or electric drive

16″ feed rolls – individual motors

Upper rolls hydraulically positioned and tensioned

All feed rolls reversible, interchangeable

High speed opening and re-setting for upper feed rolls

Water cooled main guide

Cutterheads:

Up to 32 knives/head

Top and bottom heads – one piece alloy

Steel, double journal mount (standard)

“Dura-change” (standard) Hydro-lok-optional

Optional Equipment:

Sidehead cutterheads– standard or hydro-lok

Automatic setworks – top and left sidehead

Complete lumber infeed/outfeed equipment

Plunge type sidehead jointers

Guide bar cooling unit

Mid-roll option for feeding 6’ lumber

Double profile

8″ thickness

Water cooled bed plate

Panel View operator’s station

Construction:

Heavy steel fabricated frame

Thermally stress-relieved

Modular construction