Capacity:

Thickness: 5/8″ – 4″

Width: 24″ (30″ optional)

Length: 51″ Min. self-feed

Weight: 14,000 lbs.

Vacuum:

24″- (2) 9″ dia. pipe, 5400 CFM

30″- (2) 10″ dia. pipe, 6600 CFM

Horsepower:

Top: 75 HP

Bottom: 40 HP

Hydraulic unit: 3 HP

Standard Equipments:

Anti-lap bar device

Air tensioned/released chipbreaker

LCD digital positioner – top head

Built-in top and bottom jointers with “safestone” advance

Hydraulic top and bottom head locks

Top and bottom dust hoods

Electrically interlocked safety guards with easy access

Quick release pressure bar

Electrical panel

Free standing operator’s console with FPM readout

Hosing and electrical runs

Feed system:

Mechanical

Electric-drive (2) 15 HP

Feed speed:

75 – 300 FPM

125-400 FPM Option

Upper rolls:

16″ diameter air filled tires

Electric drive

Hydraulically tensioned

Lower rolls:

12″ diameter non-powered,

Idler type, and reversible

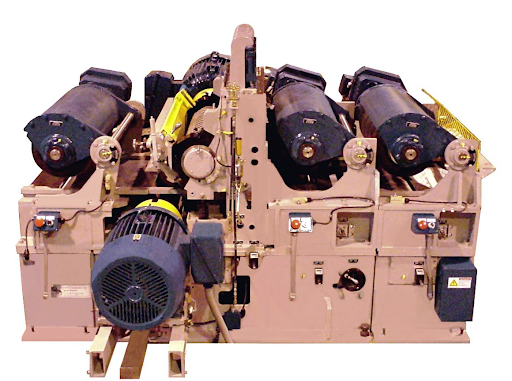

Cutterheads:

8″ diameter cutting circle – 3600 RPM

Up to 12 knives (straight)

Up to 8 row carbide spiral bits (optional)

Optional Equipment:

Automated bottom head traverse

Automated top head hoist

Automated pressure bar control

Automated set works – top head

Powered bottom rolls

Non-marking outfeed tires

Thin stock control

Small remote operator’s station

Chrome wear parts

Electric powered infeed conveyor

Construction:

Steel fabricated frame

Thermally stress-relieved

Capacity:

Thickness: 5/8″ X 4″

Width: 30″

Length: (minimum self feed) 51″

Weight: 17,500 lbs.

Vacuum: 7000 CFM-10″ diameter pipe

Horsepower:

Top – 125 HP

Bottom – 75 HP

Hydraulic Unit – 3 HP

Standard Equipments:

Chrome plated wear parts

Anti-lap bar device

Air tensioned/released chipbreaker

Power top head hoist

Shaft mounted digital position indicators

Built-in top and bottom jointers with “safe stone advance”

Hydraulic top and bottom head locks

Top and bottom dust hoods

Electrically interlocked safety guards with easy access

Quick release pressure bar

Bit grinder with “E-Z Grind” traversing feature

Electrical panel – motor starting

Electrical panel – frequency drives

Hosing and electrical runs

Feed system:

Mechanical

Electric drive: (3) 15 HP top rolls (3) 7 ½ HP bottom rolls

Feed speed: Various up to 600 FPM

Upper rolls: 16″ diameter air filled tires hydraulically tensioned

Lower rolls: 12″ diameter smooth face

Cutterheads:

10 1/4″ diameter cutting circle – 3450 RPM

12 row carbide spiral bits (standard)

Up to 20 knives –straight (optional)

“Dura-Change” cutterheads

Optional Equipment:

Non-marking outfeed rolls

Free standing operator’s console with fpm meter

Small remote operator’s station

Automated bottom head traverse

Automated top head reset

Infeed/outfeed conveyor

Hydraulic tank heater

2nd outfeed module

Off-machine grinding stand

Construction:

Steel fabricated frame

Thermally stress-relieved